In 2025, as the Paris Agreement marks its tenth year since its signing, the global energy structure has entered a critical transformation phase. While solar photovoltaic (PV) systems have become an important pillar that supports the goal of net-zero emissions, challenges in terms of power losses from generation remain. It is imperative to effectively minimize such losses and maintain system stability to ensure long-term development of such renewable energy systems.

Through data analysis and validation from practical application cases, our study found that applying super crystalline nanomaterial to the cables and connectors of solar PV modules can effectively minimize electrical conduction losses. It is a feasible and economically beneficial technology that offers a novel solution for lasting and stable operation of PV systems. In the future, we will further optimize the coating technology and extend its application to other critical power transmission points and components in solar PV installations to enhance the overall performance and lifespan of the system.

Analysis of Power Generation Losses in Solar Photovoltaic Systems

The amount of power that a solar PV system can generate is primarily determined by three factors: equipment, environment, and construction/ maintenance. In terms of equipment, the performance and lifespan of PV panels, inverters, electrical switches, transformers, and cables are directly related to power generation efficiency and system stability. Environmental factors include changes in temperature and humidity, wind speed, dust accumulation, and shading effects. These conditions can affect the light reception rate and power generation efficiency of PV modules. Additionally, construction quality and subsequent maintenance can critically impact power generation. Wiring conditions and the routine inspection frequency can affect system operations in the long-term.

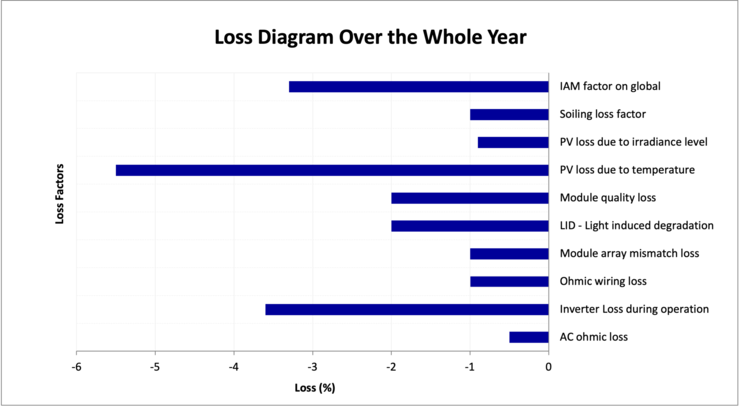

To quantify how these factors contribute to power generation losses, we used PVsyst simulation software for analysis. Results showed that power generation losses in solar PV systems occur mainly due to four reasons, which are:

- Changes in sunlight and environmental temperature, which are unavoidable natural factors.

- PV panel quality and array matching, as mismatched modules may lead to a reduction in overall system efficiency.

- Inverter operational losses, as inverter efficiency may decline over time, thus affecting the efficiency of direct-current (DC) to alternating-current (AC) conversion.

- AC and DC wiring impedance losses, that is, energy loss caused by contact impedance in cables and connectors during transmission.

Given that there are relatively mature solutions that address the degradation of PV modules and the decline in inverter operational efficiency, while the effects of sunlight and environmental temperature are external factors harder to control, our study, therefore, chose to focus on reducing wiring impedance losses in AC and DC lines. This was achieved by using super crystalline nanomaterial coating technology, which helps improve power transmission efficiency and reduce power generation losses caused by contact impedance and oxidation. This application helps enhance the long-term stability and energy utilization efficiency of the system (Figure 1).

Principles and Characteristics of Super Crystalline Nanomaterial for Conductive Applications

Super crystalline nanomaterials have high conductivity. When applied to metal contact interfaces, they form a dense and efficient current conduction path at the dual interface. This effectively reduces parasitic capacitance and inductance effects caused by uneven charge distribution, thereby improving current transmission efficiency.

Electrical metal contacts are prone to increased contact impedance due to thermal effects in high-temperature environments, affecting power transmission. Super crystalline nanomaterial materials, with their excellent lattice structure and thermal energy conduction properties, can quickly dissipate heat absorbed at the contacts, reducing the impedance increase caused by temperature rise and maintaining stable conductive performance.

When applied to the contacts of AC and DC lines, the material can effectively reduce contact impedance and enhance power output. This is especially true in high-temperature environments, where it maintains efficient transmission and minimizes power loss from contact heat dissipation. Additionally, super crystalline nanomaterial conductive materials allow contact surfaces to become smoother, reducing impedance caused by poor contact. The material also inhibits oxidation of the contacts, as the formation of oxidation layers would increase impedance and reduce power quality. In short, the application of super crystalline nanomaterial conductive technology can improve power transmission efficiency and stability, reduce energy loss, and extend equipment lifespan, bringing significant benefits to the long-term stable operation of solar PV systems.

Before evaluating how much actual benefit the application of super crystalline nanomaterial conductive materials can bring to module cables and connectors, it is necessary to conduct comprehensive field data verification to ensure the accuracy and reliability of subsequent analysis. Firstly, the data format downloaded from the monitoring system must be verified for compatibility with parsing requirements, and the arrangement of each string in the field must be understood to establish a complete baseline. Furthermore, to ensure consistent test conditions, a control group and an experimental group should be set up, and the data format should be converted and categorized to ensure correct correspondence of date and time information, ensuring the accuracy of subsequent analysis.

In terms of abnormal data detection, one must analyze in detail the current, voltage, and power fluctuations to determine whether they are influenced by shading, bird droppings, or cleaning operations, and to confirm whether the sampling interval meets testing requirements to avoid insufficient data precision. Simultaneously, data from the monitoring system must be verified to ensure accurate calculation logic, such as power matching (power = voltage x current), while the DC-AC conversion efficiency of the inverters must be reviewed to keep it within a reasonable range.

In the presence of a data anomaly, further analysis is necessary. Make sure to exclude conditions that may affect test results, such as disconnection, offline status, leakage, or data recovery issues in order to keep the current, voltage, and power data of the monitoring system accurate. Moreover, abnormal variations in accumulated power over time should be examined to identify potential influencing factors, so as to ensure that the testing process is not affected by errors.

In terms of verifying system output, it is crucial to confirm whether the AC output wiring configuration of the field inverters is correct, such as whether the configuration from single-phase to three-phase or three-phase to three-phase meets design specifications. Data cross-verification should be performed to ensure the correspondence relationship between DC input and AC output is as expected. Finally, review for data anomalies and eliminate them to enhance the credibility of the test results, providing accurate and reliable evidence for the application of super crystalline nanomaterial conductive technology.

Benefits Analysis of Applying Conductive Super Crystalline Nanomaterial to Module Cables and Connectors

ECOVE has extensive practical experience in PV system operation and maintenance, and technical optimization. To validate the feasibility of super crystalline nanomaterial conductive technology in reducing power generation losses through actual site testing, we carried out the test at a ground-mounted solar PV site that has been operational for more than five years. This site has a stable operating condition and comprehensive historical power generation data, and it matches consistent installation capacity, orientation, and tilt angle. The test period covered various climatic conditions throughout the year to ensure the results were not influenced by single environmental factors (such as sunlight intensity, shading, temperature, and humidity changes).

To ensure the accuracy and reliability of the analysis, the site was divided into three test areas. In the first and second areas, super crystalline nanomaterial were applied to the module cables and connectors, serving as experimental groups, while the third area remained untreated, serving as the control group. This comparative design allowed us to effectively evaluate the impact of super crystalline nanomaterial technology on power transmission efficiency and power generation, as well as ensure the representativeness and comparability of the test results.

Analysis of daily mean yield (DMY) and the improvement rate of power generation from inverters showed that, compared to the control group (third phase), the average power generation of the first-phase experimental group (Figure 2) increased by 7.03%, while the second-phase experimental group (Figure 3) increased by 6.18%. These results not only confirmed the effectiveness of super crystalline nanomaterial conductive technology in reducing power transmission losses, but also demonstrated its potential value in improving the power generation efficiency of solar systems.

Through real-world verification, our study shows that super crystalline nanomaterial conductive technology can reduce power generation losses by more than 6%. Based on test data estimates, the investment cost of construction can be recovered within one to two years. Furthermore, continuous monitoring shows that after two years of operation with the super crystalline nanomaterial application, the average daily power generation per season (kWh/kWp/day), excluding seasonal factors, remains consistently above the estimated baseline of 3.6 kWh/kWp/day, with no significant performance degradation (Figure 4), proving the technology’s durability and stability.

As a key takeaway, this technology not only helps improve power generation efficiency, but also enhances the stability and economic benefits of system operation. Compared to traditional contact lubricants or conductive pastes, super crystalline nanomaterial technology provides more stable conductivity under high-temperature conditions and requires less-frequent maintenance, further reducing operational costs. It is a practical and feasible technical solution that is beneficial to renewable energy development and brings substantial benefits to the global energy transition.

—Chi-Chia Liu and Wan-Yuan Chen are assistant chief engineers with ECOVE Environment Corporation.